Tailoring is no different from the fields of medicine, law enforcement and theatre in that it has its own unique jargon. Tailor-speak might be confusing at first but once you understand the origins of its’ vernacular, you’ll be impressing colleagues and friends with your new-found knowledge. If you want to be able to proudly inform people what the difference between bespoke and made-to-measure suits are, keep reading. Whether you’re shopping at Savile Row or would like to speak the universal language of threads and needles with your Milanese tailor, here’s a useful glossary for you to refer to.

1. Bespoke

A bespoke suit refers to a garment made to meet the specific requirements of the customer. It originates from the legendary tailor shops of Savile Row, where customer’s would order a fabric and have it reserved – thus they’d ‘be spoken for’. Bespoke suits are made entirely from scratch and can take up to 50 hours to make – they also require multiple fittings.

2. Half Canvas

When suits were first introduced to mass markets, all of them were made of canvas. This allows the suit fabric to breathe and drape properly. As production of suits began to increase, manufacturers began to use fusible interlinings instead, in order to be more cost and time efficient. Half-canvas suits are the best of both worlds – they have a sewn in canvas piece which sits at the chest and lapel of the jacket. Past that point, the jacket is fused.

3. Piping

Piping is located in the inside of the jacket – it serves as a barrier between the suit lining and the jacket’s fabric. Often, piping is made up of a different color lining than the jacket and serves to create contrast and make the suit look unique.

4. Interlining

Interlining is an important part of making a suit. It goes against the fabric at the inside of the jacket and acts as a kind of framework on which the rest of the suit is built upon. Interlining runs from the shoulder to the bottom of the jacket and gives shape to the chest, lapels, pockets and waist.

5. Jetted Pockets

The most formal type of pockets for coats and jackets are jetted pockets. The pockets are sewn into the lining of the jacket with a discrete opening on the side. Jetted pockets are favored for their polished and sleek appearance – they’re mostly found on formal wear like tuxedos.

6. Taper

Like the term used to describe a physique’s silhouette from the shoulders to the waist, tapers in tailoring describes the narrowing of a fabric. You’ll most often hear tailors use it to describe the narrowing of a pant leg.

7. Darts

Darts are folds sewn into fabrics for the express purpose of enhancing the wearer’s shape. You’ll most often see darts used in women’s blouses and dresses – usually, they’ll be at the bust line and provide shape to the garment.

8. Inseam

The inseam is the seam that binds the interior leg of pants. When tailoring pants, creating an inseam is vital – the length is measured from the hem of the garment where it would hit the lower ankle up to the crotch. This measurement will determine the overall leg length of the garment.

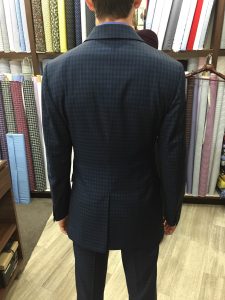

9. Vent

The vent refers to the slit located near the tail of the jacket. Tailors in England first used vents to make horseback riding in suits easier – today it’s all but a mainstay in men’s suiting. Suits can either have one, two or no vents depending on your preference and build.

10. Break

This term refers to how much creasing occurs at the bottom of trousers. The break will depend on the length of fabric that rests on the wearer’s shoes. Pant lengths are an essential part of enhancing the appearance of a pair of trousers – how you wear them comes down to personal style and body type.

Now that you’re a tailoring aficionado, you’ll have a greater knowledge of the intricacies involved in crafting the suits that you wear and love. Suiting has a rich and noble history – share your new-found familiarity of it with your local tailor.